Putting pollution to paper

- Air pollution destroys the environment and annually kills millions of people worldwide. But Graviky Labs has found a way to capture carbon emissions and convert it into commercially viable ink.

Siddhant brews his own kombucha, tries to grow his own…

On the face of things, it’s an elegantly simple and apparently obvious idea. Black ink — the most commonly used ink in industry — is made by dissolving carbon pigment in a liquid medium. Traditionally, black ink is produced by burning fossil fuels and capturing the resulting carbon emissions. The burning-fossil-fuels part is also done by a plethora of other industries that don’t capture those carbon emissions. Why would you then go through the effort of buying and burning your own fossil fuels when you can simply get the carbon from those that are doing so anyway?

That is usually how it goes with the greatest ideas. They apparently stare us in the face, languish under our very noses, until someone particularly astute and clever experiences a eureka moment. For Anirudh Sharma, such a moment occurred in 2012, when he saw a diesel generator paint a wall black with its exhaust emissions. He jury-rigged a little device that captured the soot from a burning candle and mixed it with vegetable oil and vodka to produce what would eventually become AIR-INK.

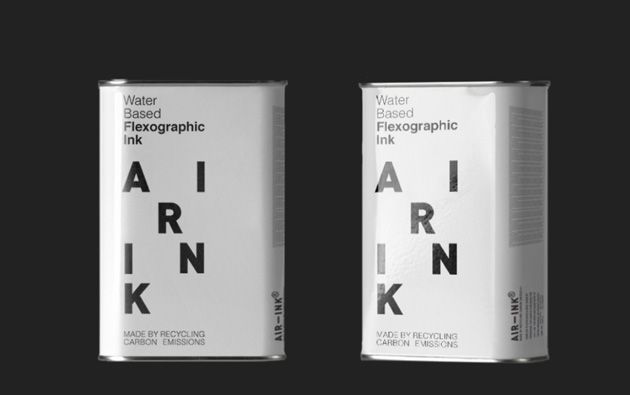

AIR-INK from Graviky Labs, first made public in 2016, is a commercially-available black ink. Since its launch, it has featured in awareness and sustainability projects by Heineken and Mastercard, and is currently available as a packaging, silk screen printing, and writing instruments ink. In 2019, TIME Magazine awarded it the title of Best Sustainability Invention of the year.

Graviky Labs, which has offices in New Delhi and Cambridge, Massachusetts, has developed a device that captures carbon particulate matter for further processing and can be retrofitted into existing emission infrastructure. AIR-INK is currently manufactured in small batches, with each batch meticulously tested for adherence to quality, safety, and biodegradability standards.

Graviky Labs used this video as part of its Kickstarter campaign to raise funds for scaling up AIR-INK production.

“Graviky’s USP lies in its ability to upcycle carbon-rich particulate matter, found in high concentrations in industrial emissions, into high-grade inks. Apart from the measurable carbon footprint reduction, AIR-INK matches or surpasses traditional petroleum-based inks. Currently, industrially available inks are made from pigments made by deliberately burning fossil fuels. Furthermore, our inks are water-based and hence better for the environment,” says Alisha Pathak of Graviky Labs.

AIR-INK is compatible with all current printing infrastructure and does not require modifications to any part of the process or equipment; it is a perfect substitute for commercially available black ink. It is presently slightly more expensive than conventional inks, though with growing economies of scale, its price is expected to come down.

While artists were early adopters of AIR-INK and continue to use it, Graviky Labs is currently working with emitters of particulate carbon to collect and upcycle emissions which would otherwise end up in landfills or water bodies. They are building scale, formulating multiple grades of AIR-INK to widen its scope of application, and working on generating carbon offsets and credits for adopters. Their grand vision is to build towards an environmentally conscious future based on a synergy of community, technology, and creativity.

“Currently, the industrially available black pigment is carbon black, and it is used in almost every black material you see around you — your phone, laptop, shoes, shoe polish, circuits, tyres, tiles, t-shirts — everything! It is bewildering how omnipresent carbon black is. The possibility of adoption of upcycled black carbon exists in all these places,” says Pathak. Graviky Labs is working with partners in various industries to understand their pigmentation needs and achieve the necessary scale to upend the traditional, greenhouse gas-emitting process of pigment production.

Most of Graviky Labs’ products are not available off-the-shelf, except for its markers, which are exclusively available at the Cooper Hewitt store in New York City. You can, however, contact them directly for any ink needs. “We are a small lab and are working towards making larger varieties of inks so as to make this industry circular and sustainable with a measurable carbon footprint reduction,” she adds.

A simple solution might once again save the day. That’s the writing on the wall.

Image and Video Courtesy: Graviky Labs

Siddhant brews his own kombucha, tries to grow his own vegetables, cycles to places, and wears plaid shirts, but insists he is not a hippie.